Experts in Custom Plastic

Fabrication For Businesses

Our business is here to help your business.

ABOUT US

Welcome to Sabo Company, where our goal is to make your business successful. With a legacy spanning over 35 years, Sabo Company has been a cornerstone in the fabrication industry. What began as a humble custom cabinet company has evolved into a custom plastic fabrication company.

At Sabo Company, we pride ourselves on our dedication to quality and precision. Our experienced team combines traditional techniques along with technology to deliver exceptional products tailored to meet our clients' exact specifications.

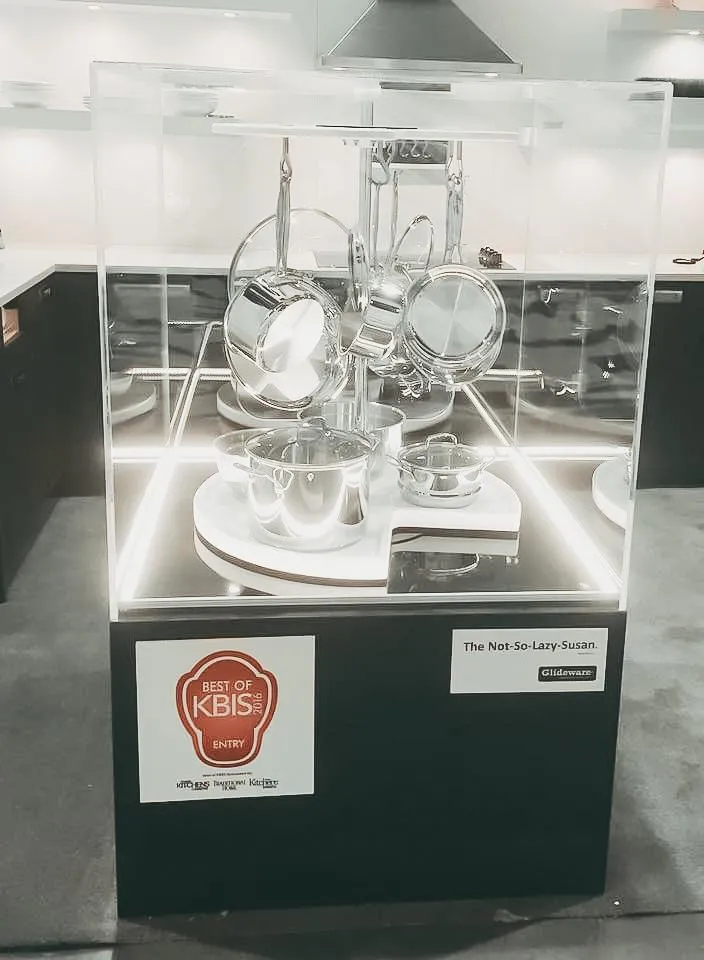

Whether you're in need of intricate components, acrylic displays or custom parts, Sabo Company is your trusted partner. Our commitment to excellence and customer satisfaction sets us apart, making us the preferred choice for discerning clients across various industries.

Experience the legacy of craftsmanship and innovation with Sabo Company. Let us bring your vision to life with our unparalleled expertise and passion for perfection.

SERVICES

Custom Fabrication

Custom fabrication encompasses the manufacturing of individualized components or products according to precise specifications, often employing advanced machinery and skilled craftsmanship. This process caters to diverse industries, offering tailored solutions ranging from prototypes to large-scale production runs.

CNC Routing

CNC routing is a computer-controlled manufacturing process that utilizes routers to cut various materials such as plastic and wood with precision and accuracy. This technology is used for producing intricate designs, prototypes, and customized parts with efficiency and repeatability.

CNC Panel Saw

Our CNC panel saw is a highly automated cutting machine used to precisely cut large sheets of materials such as acrylic, HDPE, PETG, ABS and PVC. Equipped with computer-controlled systems, these machines offer high accuracy, speed, and efficiency in cutting various sizes, enhancing productivity in manufacturing processes.

Laser Engraving

Laser engraving is a versatile technology that utilizes focused laser beams to etch designs, text, or patterns onto a wide range of materials including wood, metal, glass, and plastic with exceptional precision and detail. This process finds extensive applications in industries such as manufacturing, signage, and personalization.

Wire Heat Bending

Wire Heat bending is a fabrication technique where heat is applied to materials, such as acrylic or polycarbonate allowing them to be shaped into desired forms or angles. This method is used in industries like signage, display manufacturing, and prototyping to create curved or bent components with precision and uniformity.

Plastic Gluing and Welding

Plastic gluing and welding is a joining process that uses heat and pressure to melt and fuse plastic materials together, creating a strong and durable bond. This technique is employed in various industries, including automotive, construction, and manufacturing, for repairing plastic components, fabricating intricate assemblies, and sealing seams effectively.

I was very impressed with the work that Sabo Company did for me. They were prompt, professional, and efficient.

JOHN

Copyright © Sabo Company | Privacy Policy | Terms and Conditions | Website Design & Marketing by The Cherubini Company, LLC